- #STEPPING MOTORS AND CONTROLLERS DRIVER#

- #STEPPING MOTORS AND CONTROLLERS FULL#

- #STEPPING MOTORS AND CONTROLLERS SERIES#

To make the motor shaft turn, first one electromagnet is given power, which makes the gear’s teeth magnetically attracted to the electromagnet’s teeth.

The electromagnets are energized by an external control circuit, for example, a microcontroller. Stepper motors, on the other hand, effectively have multiple toothed electromagnets arranged around a central gear-shaped piece of iron.

Stepper motors operate differently from DC brush motors, which rotate when voltage is applied to their terminals. This technique is extensively used because it provides high accuracy as well as decreases operating noise to a large extent. The accuracy of every step can be enhanced by this small step current.

#STEPPING MOTORS AND CONTROLLERS DRIVER#

The variable step current will supply by the stepper motor driver circuit toward stator coils within the form of a sinusoidal waveform. This technique is most frequently used due to its accuracy. This technique will result in improved resolution of the stepper motor while decreasing the torque. This kind of cycle for switching two stators first &after that third stator will drive the motor.

#STEPPING MOTORS AND CONTROLLERS FULL#

This technique is fairly related to the Full step drive because the two stators will be arranged next to each other so that it will be activated first whereas the third one will be activated after that. This technique results in high torque & allows the motor to drive the high load. In this technique, two stators are activated at a time instead of one in a very less time period. This will magnetize & demagnetize the stator to move the rotor forward. In this technique every phase otherwise stator next to each other will be triggered one by one alternatively with a special circuit. It is an old method and not used much at present but one has to know about this technique. The basic method of driving a stepper motor is a single excitation mode. There are several methods to drive this motor, some of them are discussed below by taking an example of a four-phase stepper motor. Stepper motor driving techniques can be possible with some special circuits due to their complex design.

#STEPPING MOTORS AND CONTROLLERS SERIES#

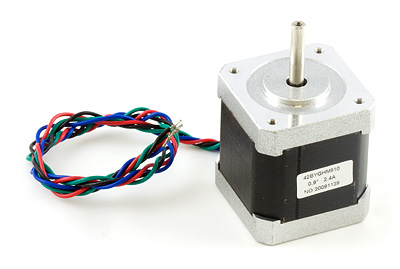

In this way, the stators are activated in a series to revolve the stepper motor. Once the stators of this motor are energized then the rotor will rotate to line up itself with the stator otherwise turns to have the least gap through the stator. The poles of the stator as well as the rotor don’t depend on the kind of stepper. In this motor, there is a soft iron that is enclosed through the electromagnetic stators. So this is the fundamental working principle of this motor. Now rotor in the motor will start to move with the rotating magnetic field of the stator. Once the supply is provided to the winding of the stator then the magnetic field will be developed within the stator. It includes a rotor which is made with a permanent magnet whereas a stator is with electromagnets. The stepper motor working principle is Electro-Magnetism. The stator’s alternative magnetizing as well as demagnetizing will shift the rotor gradually &allows it to turn through great control. So the stator will magnetize & works like an electromagnetic pole which uses repulsive energy on the rotor to move forward. The stepper motor can be controlled by energizing every stator one by one. The stator is arranged near to rotor so that magnetic fields within the stators can control the movement of the rotor. of the stator which is wound through a magnetic coil all over it. It includes a permanent magnet like Rotor which is in the middle & it will turn once force acts on it. The construction of a stepper motor is fairly related to a DC motor.

0 kommentar(er)

0 kommentar(er)